Baenjineri ba fumanehang litšebeletso tsa tšepe e sa hloekang u thaepa screw conveyor

Tlhaloso ea Sehlahisoa

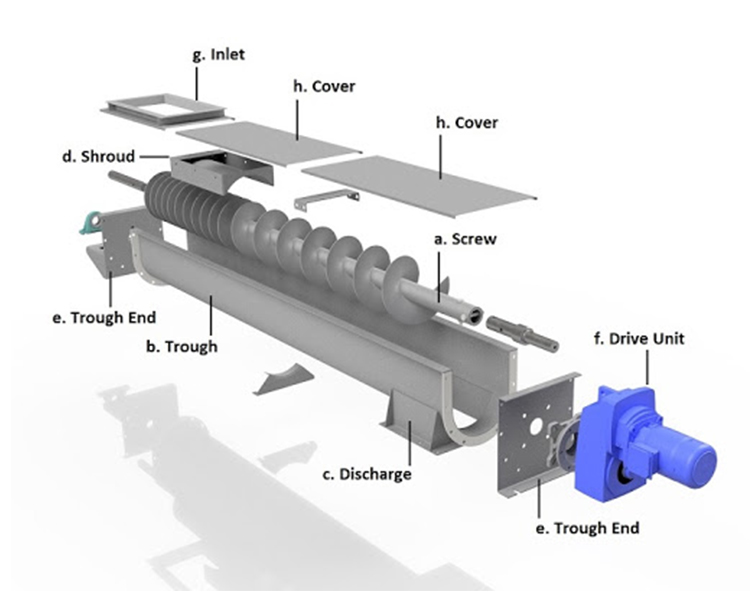

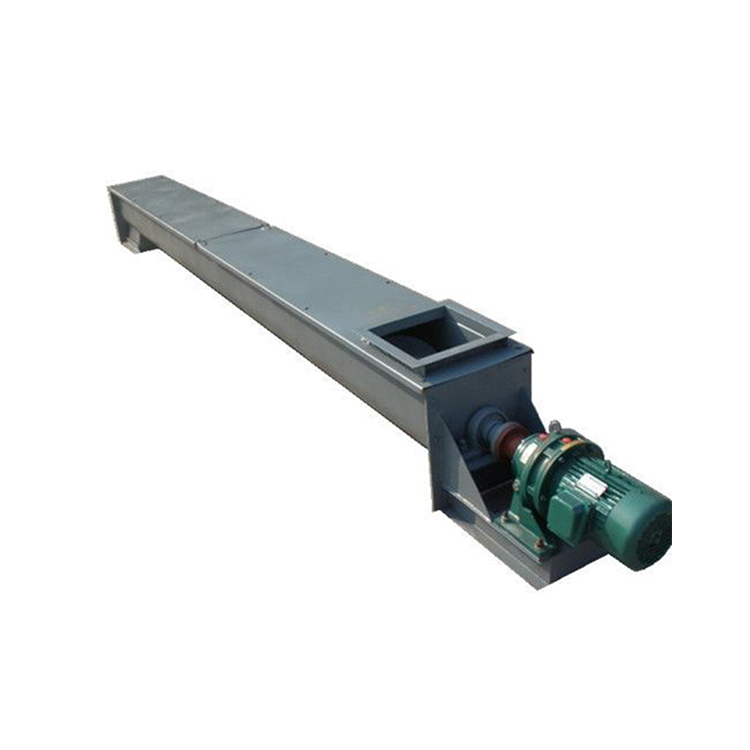

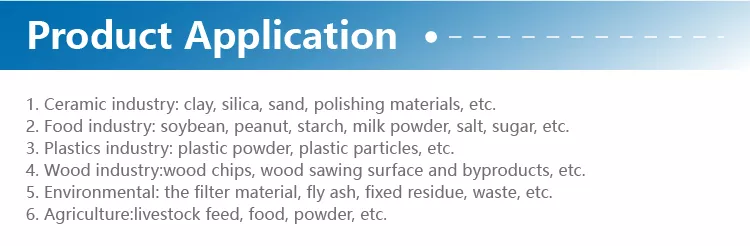

Screw conveyor ke mofuta oa mochini o sebelisang enjene ho khanna ho potoloha ha spiral le ho sututsa lisebelisoa ho fihlela sepheo sa ho tsamaisa.E ka tsamaisoa ka mokhoa o otlolohileng, oblique kapa o otlolohileng, 'me e na le melemo ea sebopeho se bonolo, sebaka se senyenyane sa likaroloana, ho tiisa hantle, ts'ebetso e bonolo, tlhokomelo e bonolo, le lipalangoang tse koetsoeng tse bonolo.Li-conveyors tsa screw li arotsoe ka li-conveyors tsa shaft screw le li-conveyors tsa screw tsa shaftless ka mokhoa oa ho tsamaisa.Ka chebahalo, li arotsoe ka li-conveyors tse bōpehileng joaloka U le li-screw conveyors.Li-conveyors tsa "Shaft screw" li loketse lisebelisoa tsa phofo tse sa bonahaleng le lisebelisoa tse nyane (mohlala: samente, molora oa fofa, kalaka, lijo-thollo, joalo-joalo), athe li-screw conveyors tse se nang shaftless li loketse li-conveyors tse nang le lisebelisoa tse nang le viscous le moea o bonolo. .(Mohlala: sludge, biomass, litšila, joalo-joalo) Molao-motheo oa ts'ebetso oa "screw conveyor" ke hore lehare le potolohang la screw le sututsa thepa hore e fetisoe ke screw conveyor.Matla a thibelang thepa ho potoloha ka lehare la conveyor screw ke boima ba thepa ka boeona.The frictional resistance of the screw conveyor casing to the material.Li-spiral blades tse cheselitsoeng holim'a shaft e potolohang ea screw conveyor li na le bokaholimo bo tiileng, bokaholimo ba lebanta, bokaholimo ba lehare le mefuta e meng ho latela lisebelisoa tse fapaneng tse lokelang ho fetisoa.The screw shaft ea screw conveyor e na le motsu qetellong ea tataiso ea motsamao oa lintho tse bonahalang ho fana ka matla a axial reaction a screw ka thepa.Ha bolelele ba mochine bo le telele, ho lokela ho eketsoa ho emisoa ha mahareng.

| Ntho ea Mohlala | GLS150 | GLS200 | GLS250 | GLS300 | GLS350 | GLS400 | |

| Spirochete bophara(mm) | 150 | 200 | 250 | 300 | 350 | 400 | |

| Hlahisa bophara ba phala(mm) | 165 | 219 | 273 | 325 | 377 | 426 | |

| Lumella phetisetso Angle(α°) | 0-60 | 0-60 | 0-60 | 0-60 | 0-60 | 0-60 | |

| 0-30 | 0-30 | 0-30 | 0-30 | 0-30 | 0-30 | ||

| 0-15 | 0-15 | 0-15 | 0-15 | 0-15 | 0-15 | ||

| Boholo ba bolelele ba phetiso(m) | 12 | 13 | 14 | 15 | 16 | 16 | |

| 16 | 17 | 18 | 21 | 22 | 22 | ||

| 20 | 22 | 25 | 27 | 28 | 28 | ||

| Boholo ba matla a phetiso(t/h) | 30 | 48 | 80 | 110 | 140 | 180 | |

| 22 | 30 | 50 | 70 | 100 | 130 | ||

| 15 | 20 | 35 | 50 | 60 | 80 | ||

| Matla a kenyang(KW) | L <6m | 2.2-7.5 | 3-11 | 4-15 | 5.5 -18,5 | 7.5-22 | 11-30 |

| L=6~10m | 3-11 | 5.5-15 | 7.5-18.5 | 11-22 | 11-30 | 15-37 | |

| L>10m | 5.5-15 | 7.5-18.5 | 11-22 | 15-30 | 18.5-37 | 22-45 | |

Melemo ea sehlahisoa sa U screw conveyor:

1. Ho kenya le ho qhaqhoa ha ho hloke motsamao oa axial, mandrel e telele, ho leketla ho fokolang, le lintlha tse fokolang tsa ho hlōleha.

2. Amohela sebopeho sa bophara bo fapaneng ho eketsa molumo oa ho fanyeha ho fanyeha

3. Ka har'a marang-rang, e ka potoloha ka bolokolohi le khanyetso e fetisang ho qoba jeme ea thepa kapa li-blockages.

4. Litulo tse nang le hlooho le mohatla li ka ntle ho khetla, ka bophelo bo bolelele ba tšebeletso

5. Ts'ebetso e ntle ea ho tiisa, ts'ebetso e tsitsitseng le e ka tšeptjoang, ho kenya lintlha tse ngata le ho laolla le ho sebetsa bohareng.

Ho paka le ho romela